The AI revolution has led to changes in the workforce. Process and repetitive jobs like those found in warehouses and factories are being given to robot workers. This rise of the robot workforce presents a key challenge for businesses. How do they effectively manage and optimize dozens, or even hundreds, of different robots working together?

This is where Robot Fleet Management (RFM) comes in. An RFM system is a centralized software platform that acts as the "brain" for your robot fleet. It uses advanced algorithms to coordinate tasks, plan routes, and monitor statuses to boost operational efficiency.

This article will explain the critical role of RFM, its essential functions, and provide a guide on how to choose the right system for your business. We will also explore the challenge of vendor lock-in and how solutions like Mobile Device Management (MDM) can complement your robot fleet management strategy.

1Why Robot Fleet Management Is Crucial

Imagine a warehouse with fifty robots from various manufacturers, all working in the same space. Without a centralized system, you would face several significant problems:

- Vendor Fragmentation: You have different brands and types of robots for different tasks, like delivering food and cleaning floors. These robots can’t communicate with each other. Think of it like trying to lead an army where every soldier speaks a different language.

- Lack of Visibility: From your manager’s office, you can't see the real-time location, battery level, or task status of your robots. This lack of situational awareness makes it impossible to make informed decisions, leading to delays and missed opportunities.

- Inefficiency and High Costs: Manual scheduling is slow and prone to errors. As a result, uncoordinated robots may follow inefficient paths, leading to collisions, traffic jams, and wasted time and energy, directly impacting your bottom line.

- Unplanned Downtime: Without an automated way to predict or monitor robot health, you only find out a robot is broken when it stops working, causing disruptions to your entire operation and increasing maintenance costs.

RFM systems are designed to directly address these pain points. By centralizing control, they help you maximize efficiency, reduce costs, and ensure smooth, uninterrupted operations.

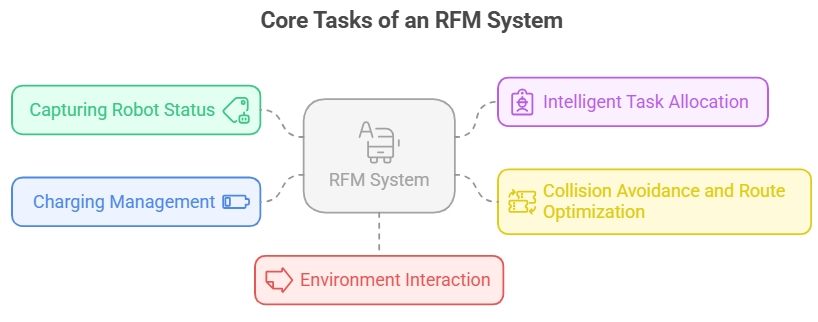

2The Core Tasks of an RFM System

An effective RFM system handles a range of tasks to keep your robot fleet running smoothly. Its primary functions include:

- Capturing Robot Status: Continuously collecting real-time data on each robot's location, battery level, and task status (in service, idle, or in an error state).

- Intelligent Task Allocation: Using conditions like time, distance, and robot capabilities, the system intelligently selects the best robot for a new task. This action ensures optimal resource utilization.

- Collision Avoidance and Route Optimization: Planning efficient routes for each robot and actively managing traffic to prevent them from converging at the same point, which could cause congestion or collisions.

- Charging Management: Recognizing when a robot's battery is low and automatically sending it to a charging station.

- Environment Interaction: Interfacing with building facilities like automatic doors and elevators, allowing robots to seamlessly navigate the environment without human intervention.

3How to Choose a Robot Fleet Management System?

Selecting the right RFM system is a critical decision. Here’s a breakdown of the key factors to consider, including market classifications and rollout strategies.

3.1 RFM Software Categories: Monitoring vs. Management

The market offers two main types of RFM software:

- Fleet Monitoring Systems:

These platforms, such as Formant, Freedom Robotics, and Brain Corp, are primarily focused on providing real-time status information for individual robots to take action on battery, temperature, or camera feeds. Their key limitation is a lack of coordination; they cannot coordinate behaviors between multiple robots. If you send two robots to the same spot, they may collide or get stuck, because the system doesn't actively manage their interactions. - Fleet Management Systems:

These are the true overseers of a robot fleet. They act as large-scale planners that adapt to changing conditions and intelligently decide which robot should perform which task. They are designed to coordinate and manage all robots as a single, cohesive unit. Today, these systems are often tied to a specific robot brand, like MiR Fleet (for MiR robots) or Fetch Core (for Fetch robots).

3.2 Key Considerations for System Selection

1. Business Scenario & Functional Focus

Your choice of system should align with your specific business needs.

- General-Purpose Platforms:

Solutions like Meili Robots are highly flexible and suitable for managing a variety of robot types and brands in a single, user-friendly platform. - Specialized Vertical Solutions:

Industrial Inspection: Boston Dynamics Orbit is focused on inspection and creating digital twins of facilities.

Warehouse Piece-Picking: RightHand Robotics specializes in picking individual items.

Construction Sites: Karelics offers features like BIM integration and virtual walls, designed specifically for construction environments.

Industrial Logistics: Companies like Fives Group (real-time traffic management) and Addverb's Movect (dynamic task allocation) provide highly optimized solutions for logistics.

2. Deployment Method

Decide whether a cloud-based, on-premise, or hybrid solution best suits your needs, considering factors like data security, control, and maintenance costs. There are three options:

- Cloud: Low upfront cost, flexible, and accessible from anywhere.

- On-Premise: High data security and full control, but requires more initial investment and maintenance.

- Hybrid: Combines the benefits of both, managing sensitive data locally while leveraging the cloud for other services.

3. Build vs. Buy

Should you build a custom system using open-source frameworks like Open-RMF or invest in a commercial, off-the-shelf platform? The answer depends on your in-house technical expertise, budget, and timeline.

4. Usability & Algorithm Quality

Evaluate the system's user central interface for clarity and ease of use. Critically assess the intelligence of its underlying processes for task scheduling, route planning, and collision avoidance—these are the heart of an effective RFM system.

4Breaking Vendor Lock-in: The Challenge and an MDM Solution

A major challenge in the robotics industry is vendor lock-in, where using a robot from one manufacturer forces you to use their proprietary management software. This prevents you from integrating a fleet of different robots under one system, increasing costs and management complexity.

The industry is responding with standards like VDA 5050 and MassRobotics, as well as open-source solutions like Open-RMF, to enable different robots to communicate with each other.

MDM as a Solution for Basic Needs

For situations where vendor lock-in is an issue and your needs are straightforward, for example, focused on IT-level device management and security, MDM software like AirDroid Business can be a more suitable and cost-effective choice than a complex RFM system. MDM's core strengths lie in managing the individual computing device within the robot, not the robot's collective behavior.

This approach is best for:

- 1. Single-Task Robots: Robots that perform simple, repetitive tasks without complex navigation or interaction.

- 2. IT Security and Compliance: The primary goal is to ensure the robot's operating system and applications are secure and compliant, with regular patches and updates to prevent malicious attacks.

- 3. Small Fleets: When the fleet size is small and there is no need for complex cooperative work.

5MDM as a Device-Level Complement to RFM

Many modern robots, particularly those with sophisticated features, are built on embedded smart devices running Android, Windows IoT, or other mobile operating systems. Mobile Device Management (MDM) is the perfect tool to manage and secure these "robot brains" at the device level.

MDM and RFM work on different but complementary layers: RFM manages the collective behavior of the fleet, while MDM focuses on the health, security, and software of the individual device within the robot.

Why You Need MDM

MDM provides crucial functions that traditional RFM might not, including:

- Remote Control & Troubleshooting: If any of the robots’ screens freeze or an app crashes, MDM allows you to view and control the devices, access files, or restart them, all from one central location. This saves time and money in manual site visits.

- Unified Software Management: You can remotely and seamlessly install, update, or uninstall apps and firmware across the entire fleet, ensuring all devices are running the latest, most secure versions. This process can be done individually or across multiple robots at once.

- Robust Security: Enforce security policies, encrypt data, and remotely lock or wipe devices if they are lost or stolen, protecting sensitive data.

- Location Tracking: Track the physical location of the robot's internal device and set up geofencing to ensure it operates within its designated area.

- Device Health & Performance: Monitor device-level metrics like battery health, CPU usage, and app stability, providing valuable data for more precise predictive maintenance.

AirDroid Business Customer Case Study: Robot Vendor

A company specializing in robot sales and rental faced a major challenge after deploying hundreds of Android 10-based robots, including popular delivery models, across various client sites. As a vendor, they were responsible for providing continuous support and ensuring the robots' stable operation. Manually managing each robot at separate locations became a logistical and financial burden, leading to significant delays in support, poor customer satisfaction, and security risks.

- Challenge: The robot vendor needed a way to remotely and efficiently manage the software and devices across a large, distributed fleet. They struggled with remote troubleshooting, deploying app updates, and ensuring that each robot was locked into a single, dedicated operational app to prevent unauthorized use.

- Solution: The company implemented AirDroid Business, a powerful MDM software, to create a centralized management solution. They used its Kiosk Mode feature to lock all robots into a specific delivery or service application, ensuring single-purpose use. Additionally, using the Remote Control feature, the technical support team could view and operate robot screens in real time, quickly diagnosing and resolving application issues without needing to be on-site. The bulk deployment feature also allowed them to remotely push system and app updates, ensuring all robots were running the latest, most secure software.

- Result: The robot vendor dramatically improved service efficiency and reduced operational costs by eliminating on-site technical visits. Kiosk Mode ensured the security and purpose-driven use of the robots, while Remote Control reduced issue resolution time by 70%. By remotely updating software, they ensured consistent software and security across their entire robot fleet, significantly boosting customer satisfaction and solidifying their market position as a reliable robotics supplier.

5Conclusion: Empower Your Robot Workforce with RFM

In summary, Robot Fleet Management is essential for businesses that are replacing their human workforce with robots. It provides the intelligence and control needed to transform individual robots into a powerful, efficient, and cohesive workforce. As technology evolves, RFM systems will become even more intelligent with AI-driven capabilities and deeper integration with solutions like MDM. By understanding your needs and choosing the right RFM system, you can unlock the full potential of your robot fleet and pave the way for a more efficient and intelligent future.

Leave a Reply.