Real-Time Logistics: How MDM Monitoring Ensures Device Continuity

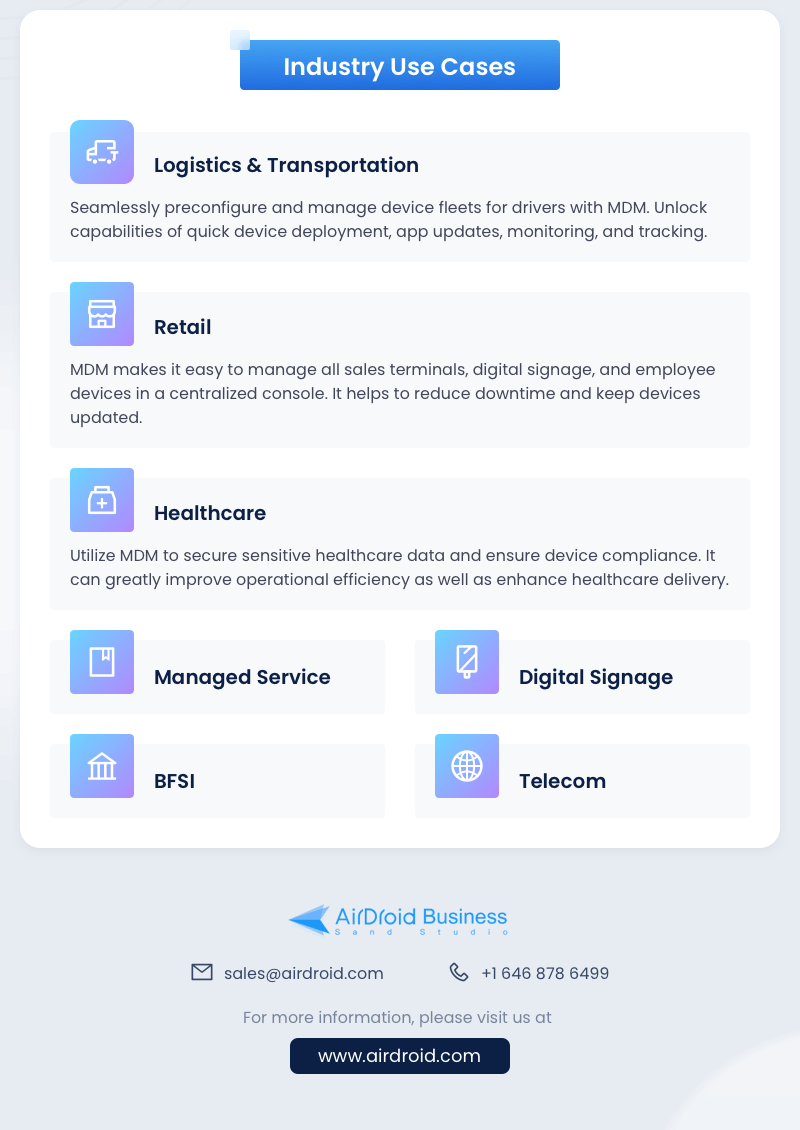

From barcode scanners in warehouses to tablets for field workers, mobile devices have become the backbone of modern logistics operations. However, while these tools are essential for seamless supply chain management, when these devices fail due to downtime, malfunction, or connectivity issues, it can have a major impact on every aspect of the company.

Whether it’s a direct impact on operations, delaying delivery schedules, or causing reputational damage, these disruptions can be a costly setback. That is why it is essential for companies to take steps to prevent this, and real-time Mobile Device Management (MDM) monitoring is a vital aspect of ensuring uninterrupted performance and security.

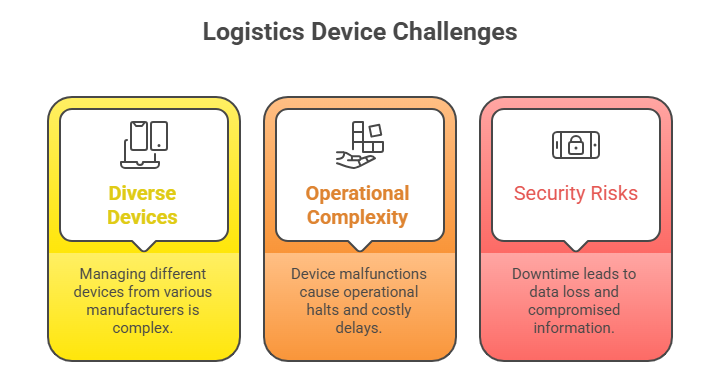

1Continuity challenges in logistics devices

Logistics operations depend on diverse mobile devices, each with unique requirements, and that means managing this complexity presents several challenges:

- 1) Diverse range of devices

Logistics companies often use a mix of smartphones, rugged tablets, handheld scanners, and vehicle-mounted computers, all of which come from different manufacturers and run on various operating systems with distinct hardware specifications. This makes it a daunting prospect trying to ensure consistent performance across such a wide ecosystem. - 2) Operational complexity

When a device malfunctions in a distribution center or during a delivery route, operations can very easily grind to a halt. Traditional IT support may not detect the problem until it’s reported by an employee, wasting valuable time. That inability to quickly diagnose and fix remote issues can result in costly delays. - 3) Security and data risks

Device downtime doesn’t just cause operational slowdowns; it can also lead to data loss, inaccurate inventory tracking, and compromised customer information. In an industry where accuracy and timing are critical, these risks can escalate quickly and cause significant reputational damage.

| Aspect | Traditional IT Support | Real-Time MDM Monitoring |

|---|---|---|

| Issue Detection | Reactive, depends on user reports | Proactive, automatic detection |

| Response Time | Delayed, manual coordination | Instant alerts and automated actions |

| Troubleshooting | On-site or manual remote access | Remote, seamless configuration and fixes |

| Continuity Impact | High risk of prolonged downtime | Minimal disruption with predictive insights |

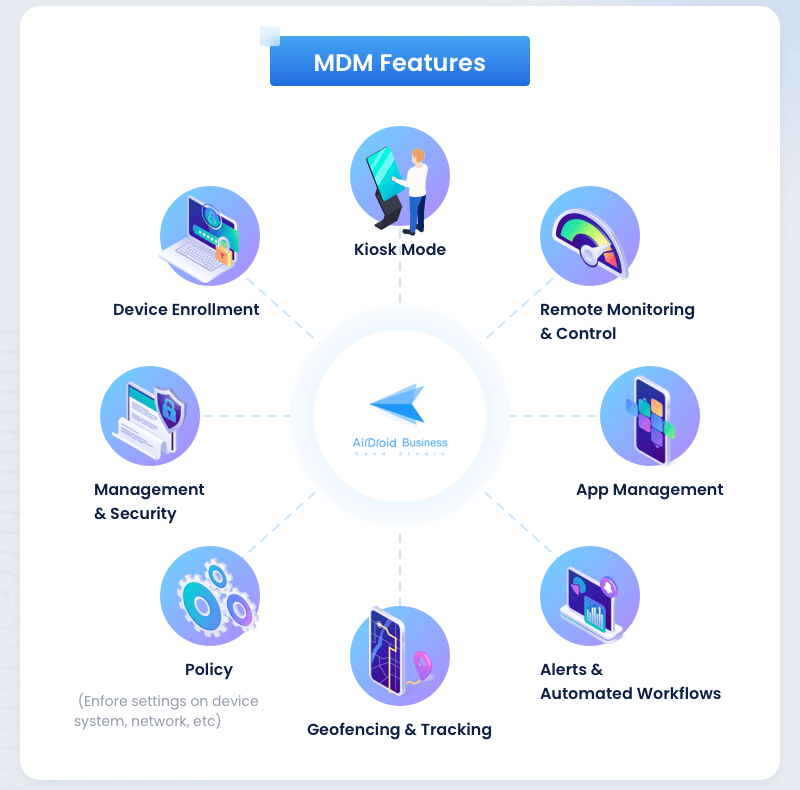

2Core functions of real-time MDM monitoring

To address these challenges, logistics companies need a comprehensive monitoring system built specifically for their device environment. Real-time MDM monitoring delivers four core functions that make it indispensable.

1. Real-time status tracking

MDM platforms provide visibility into each device’s online/offline status, application performance, network connectivity, hardware condition, and battery health. Managers can view this information from a centralized dashboard, enabling them to stay ahead of potential disruptions.

This real-time visibility allows logistics teams to prioritize resources, monitor usage trends, and identify underperforming devices before they cause downtime. It also creates accountability by giving operations teams a clear picture of how devices are being used in the field.

2. Automated alerts

With automated alerts, IT teams receive immediate notifications when anomalies occur, such as app crashes, battery overheating, or network drops. These real-time warnings significantly reduce response times, allowing issues to be addressed before they escalate into major operational setbacks.

Alerts can also be customized based on severity or device role, ensuring critical issues are prioritized. This level of automation eliminates the need for manual monitoring and ensures that IT staff can focus on rapid problem resolution rather than constant supervision..

3. Remote troubleshooting and configuration

Sending IT personnel on-site to repair devices wastes time and resources, and with remote troubleshooting, administrators can quickly access devices, reset settings, deploy updates, or reconfigure applications without requiring physical presence.

This keeps logistics workflows running smoothly, even when devices are spread across multiple warehouses or routes. Remote capabilities also enable bulk configuration updates, ensuring consistency across fleets of devices, while reducing downtime and minimizing disruptions to employees who rely on their tools for real-time operations.

4. Data-driven predictive maintenance

One of the most powerful aspects of MDM monitoring is the ability to analyze historical device data for patterns of recurring issues, allowing companies to potentially predict failures before they happen.

This predictive maintenance approach helps prevent downtime, extends device lifespans, and reduces repair costs; for example, if a batch of scanners shows a trend of battery degradation after a certain number of cycles, IT can schedule proactive replacements. This foresight prevents unexpected breakdowns and helps organizations budget more effectively for long-term device investments.

3Real-world use case: Transtira logistics

One of the clearest examples of how real-time MDM monitoring ensures logistics device continuity comes from Transtira, a European logistics company specializing in freight and fleet management.

Challenges Faced by Transtira: Inconsistent Device Management Across Borders

Transtira, a European logistics company, operates across multiple countries, relying heavily on tablets and smartphones for route navigation, driver communication, and cargo documentation. However, managing such a diverse fleet led to several recurring challenges. Devices ran on inconsistent configurations, causing confusion among staff and disrupting operations. Frequent app malfunctions and network drops created delays in deliveries, while a lack of centralized visibility meant that IT teams often had to wait for drivers to manually report issues before they could begin troubleshooting. This reactive approach resulted in unnecessary downtime, slowed deliveries, and an increase in IT overhead, making it difficult to maintain smooth operations.

How AirDroid Business MDM Solved Transtira’s Device Management Challenges

To address these challenges, Transtira implemented AirDroid Business MDM with real-time monitoring capabilities. This solution allowed them to gain centralized visibility over their entire fleet of device. IT teams could instantly see device status—whether devices were online or offline, their battery health, and their network connectivity. Anomalies such as overheating or app crashes triggered real-time alerts, enabling the team to act swiftly and prevent any disruptions. Remote troubleshooting became possible, allowing IT to push updates, adjust app settings, and reconfigure devices across multiple regions without needing physical access. Bulk policy deployments ensured consistency by guaranteeing that every device was running the same configurations, minimizing confusion and errors among drivers.

Results: Increased Efficiency and Seamless Operations with Real-Time MDM Monitoring

With real-time monitoring and management through AirDroid Business, Transtira saw a dramatic reduction in device downtime and significant improvements in their delivery schedules. Tasks that once took hours of manual support were now resolved in minutes. This efficiency boost allowed drivers to stay productive, as their tools were always available and functioning consistently. The shift from a reactive, problem-solving approach to a proactive continuity management model ensured that Transtira’s operations ran smoothly, even while managing hundreds of devices across multiple countries. This case highlights how logistics companies can improve both operational efficiency and service reliability with the right MDM solution.

4Real-time visibility in logistics operations

Real Time Tracking

With real time logistics tracking, managers can see trucks, drivers, and cargo on the move. This kind of logistics real-time visibility helps dispatchers reroute vehicles when traffic builds up or when a delay threatens customer commitments. A connected real time logistics & transportation platform puts all this information in one place, so decisions can be made without guesswork.

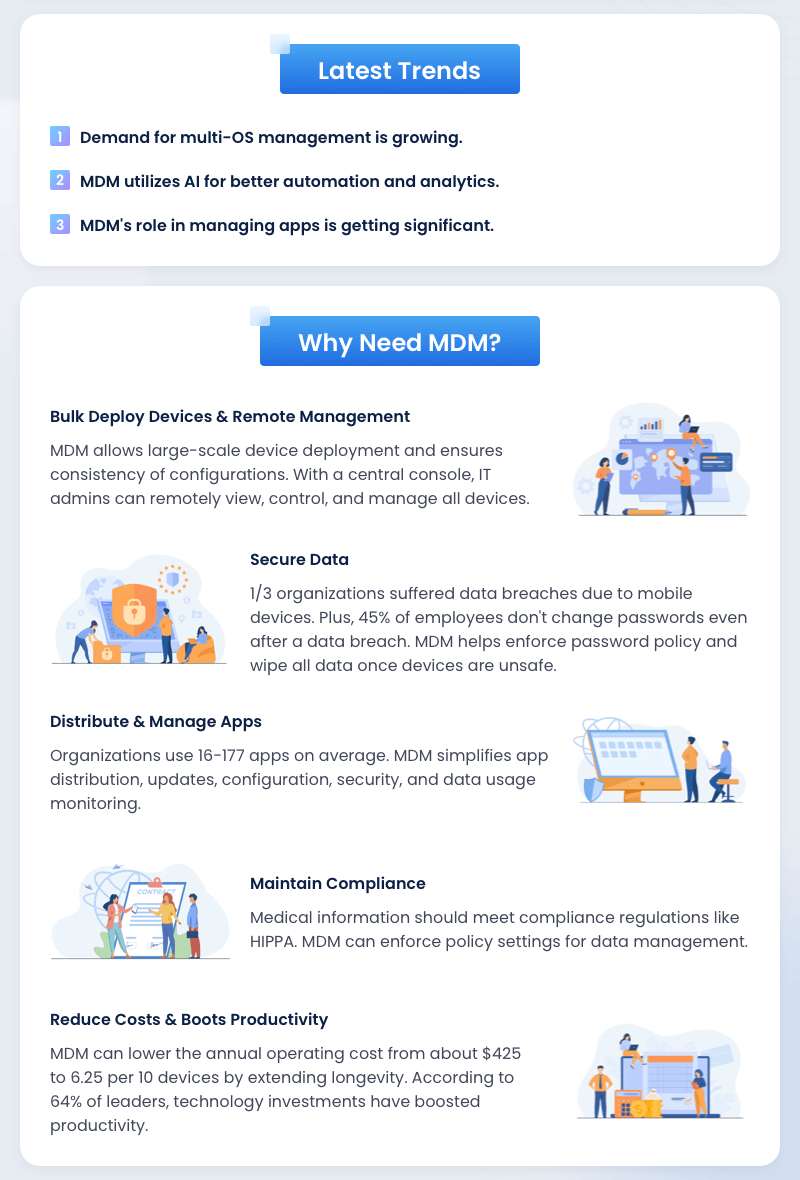

Real Time Analytics

Data becomes more useful when it turns into action. Real time logistics analytics highlights bottlenecks, late-running routes, or equipment that’s underperforming. Some companies are starting to use AI tools for real-time data analysis in logistics to spot patterns, predict slowdowns, and make adjustments before issues spread.

Real Time Security

Keeping freight safe is also part of the job. Logistics real-time video surveillance lets teams monitor warehouses, yards, and loading docks as events happen. Linked with device alerts, it gives operations teams a way to react quickly if something suspicious occurs, adding another layer to overall logistics security solutions.

Managing Returns and Delays

Real-time tools don’t only help outbound deliveries. Real-time reverse logistics decision-making speeds up the processing of returned goods, while real-time systems logistics response to delays gives managers options to adjust schedules on the fly and keep operations moving.

5Protecting your operations

Mobile devices are the lifeline of logistics operations. Yet their diversity, operational complexity, and inherent risks create vulnerabilities that can damage efficiency and customer satisfaction. Real-time MDM monitoring offers a proactive solution, providing continuous visibility, instant alerts, remote troubleshooting, and predictive insights that ensure device continuity.

By implementing a solution like AirDroid Business, logistics companies can safeguard their operations against downtime, protect critical data, and deliver consistent, reliable service. In the competitive world of global logistics, where every second counts, real-time monitoring is no longer optional but a necessity for continued success.

6FAQs about real time logistics

1. What is real-time tracking in logistics?

Real-time tracking in logistics refers to the ability to monitor the location and status of shipments, vehicles, and drivers in real time. By using GPS, sensors, and connected devices, logistics companies can track goods from the warehouse to the final destination, ensuring smooth operations and timely deliveries. This tracking capability helps businesses avoid delays and make quick decisions to reroute deliveries if needed.

2. How does real-time visibility improve supply chain management?

Real-time visibility in supply chains provides managers with immediate insights into the status of inventory, shipments, and operations. This visibility helps companies respond to disruptions quickly, optimize delivery routes, and reduce delays. By having access to real-time data, logistics companies can make more informed decisions, reduce risks, and improve overall efficiency. Real-time visibility also enhances collaboration between supply chain partners.

3. What are the benefits of real-time logistics analytics?

Real-time logistics analytics allows companies to continuously analyze operational data, identifying trends, bottlenecks, and inefficiencies. With this information, logistics companies can predict potential delays, optimize routes, and improve overall performance. AI-driven real-time logistics analytics also helps businesses make proactive adjustments before problems escalate, ensuring smooth operations and timely deliveries.

4. How does real-time MDM monitoring help with device management?

Real-time Mobile Device Management (MDM) monitoring helps logistics companies manage and secure their fleet of mobile devices in real time. It provides visibility into device performance, usage, and status, allowing IT teams to detect problems early and resolve them remotely. Real-time MDM monitoring helps minimize downtime, ensuring devices are always available and fully functional, which is essential for maintaining continuity in logistics operations.

5. What is the role of real-time video surveillance in logistics security?

Real-time video surveillance in logistics allows companies to monitor their facilities, trucks, and cargo in real time. This technology helps ensure the security of goods during transportation and at warehouses. When combined with real-time alerts, it provides operations teams with the ability to respond immediately to any suspicious activity or potential security breaches, adding an extra layer of protection to logistics operations.

6. How does AirDroid Business improve real-time logistics operations?

Airdroid Business provides logistics companies with a comprehensive MDM solution that ensures real-time device monitoring, remote troubleshooting, and centralized visibility across fleets of mobile devices. By implementing AirDroid Business, companies can streamline operations, reduce downtime, and ensure that all devices are properly managed and configured for optimal performance, leading to improved logistics efficiency and service reliability.

Leave a Reply.