The 4 Biggest Challenges in Modern Logistics Mobile Device Management

Did you know that the global digital logistics market is predicted to reach over $120 billion by 2032? That’s nearly three times the size it is currently, which means those traditional clipboards and barcode scanners are quickly being switched for smart devices, IoT sensors, and real-time dashboards. The transition from conventional manual operations to data-driven, digital-first logistics is revolutionary, but it is also posing a number of challenges in the logistics industry.

In this article, we thought we would take a closer look at four of the biggest new challenges in the logistics industry when it comes to mobile device management, and what you can do to overcome them.

Challenge 1: The explosion of device complexity

A decade ago, managing the mobile device fleet across warehouses was simple: most staff carried rugged barcode scanners that did one job and needed little IT attention. Today, logistics teams manage dozens of device types — smartphones, tablets, rugged handhelds, vehicle tablets and an expanding field of IoT sensors — each with its own OS, update cadence and failure modes.

Centralized logistics device management is critical to reduce failure points and scale operations efficiently.

Then vs Now — device landscape

| Aspect | Then (10 years ago) | Now |

|---|---|---|

| Devices | Mostly rugged barcode scanners with single-purpose functions. | Diverse mix of smartphones, tablets, handheld terminals, IoT sensors. |

| Management | Minimal IT involvement; few devices to configure or update. | IT must manage hundreds of devices across different OS platforms. |

| Updates | Rare firmware updates; stability was the norm. | Frequent OS patches, app updates, and security fixes needed. |

| Risk Level | Low — devices carried little sensitive data. | High — devices store shipment info, customer data, and inventory details. |

| Impact of Failure | Minor — delays in scanning could be fixed manually. | Critical — a failed device can spoil shipments or disrupt route optimization. |

Why this matters

- Fragmentation = workload: Multiple platforms mean constant patching, provisioning and compatibility checks — manual workflows don't scale.

- More failure points: One out-of-sync temperature sensor or an unpatched route tablet can cascade into spoilage, missed deliveries or wrong routing.

- Security surface grows: Every device type adds possible configuration mistakes, weak credentials or unmonitored ports.

- Cost & scale pressure: As device fleets grow, OPEX (updates, data, SaaS) replaces simple CAPEX — planning becomes harder.

Real-world impact

Temperature and cold-chain failures are one of the most costly risks in logistics. Industry analyses estimate billions in annual losses — as much as US$20-35 billion per year — due to temperature-related failures in pharma and perishable supply chains.

Another 2024 white paper by TITAN Containers highlights a similar figure, estimating around US$35 billion in annual losses linked to cold storage breakdowns and poor monitoring .

These numbers show why robust device monitoring and incident controls are mission-critical — a single syncing failure in temperature sensors can cascade into spoiled goods, missed deliveries, and multimillion-dollar losses.

Challenge 2: The urgency of data security

It wasn’t long ago that logistics security meant locking the office door. Warehouse devices rarely held sensitive data, so breaches were more of an inconvenience than an existential threat.

Today, the picture is completely different: mobile devices now carry real-time shipment tracking, customer addresses, and live inventory data. A single lost phone can expose thousands of records and paralyze operations. The collapse of KNP Logistics in 2025—after hackers locked its systems and left 700 employees jobless—shows just how fast a weak link can bring down an entire supply chain.

To put this shift into perspective, here’s a clear comparison of how logistics security has evolved over time:

| Then | Now |

|---|---|

| Data stored in office servers, low exposure risk | Every driver’s tablet carries live customer + shipment data |

| Security = physical locks + backups | Need for encryption, remote wipe, zero trust |

| Breach impact: minor disruption | Breach impact: millions lost + reputational damage |

Cybercriminals are now deliberately targeting mobile endpoints, exploiting outdated systems and unsecured Wi-Fi links. That means modern security controls are not “nice-to-haves”—they are survival essentials. Companies without remote wipe, policy enforcement, and real-time monitoring aren’t just risking IT downtime—they are risking their license to operate in a trust-driven industry.

Challenge 3: The demand for real-time everything

Traditional logistics relied on end-of-day updates for deliveries and inventory, which created unavoidable blind spots. Managers often made decisions based on outdated information, leading to delays and inefficiencies. Today, supply chains demand instant, live insights into shipments, vehicles, and warehouse conditions, and companies that lag behind risk significant operational and financial setbacks.

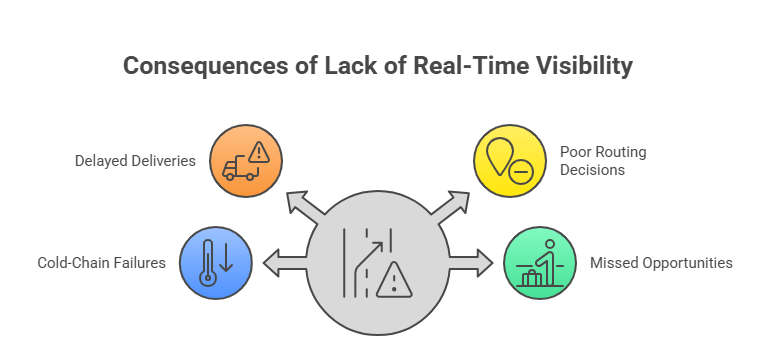

Without real-time visibility, companies face:

- Delayed deliveries: A single missed update can cascade into late shipments and frustrated customers.

- Poor routing decisions: Managers react to outdated conditions, leading to inefficiencies and increased fuel costs.

- Cold-chain failures: Temperature-sensitive shipments require constant monitoring—delayed alerts can result in millions of dollars in losses.

- Missed opportunities: Lack of live inventory visibility prevents dynamic stock reallocation and proactive problem-solving.

In short, real-time logistics visibility is no longer optional—it’s a strategic differentiator. Robust connectivity, automated alerts, and live dashboards are essential to operational efficiency, risk mitigation, and maintaining customer trust.

Challenge 4: A fundamental shift in the cost structure

Before the digital transformation, managing technology in logistics was relatively simple. Companies purchased hardware—barcode scanners, desktops, and printers—and planned for occasional maintenance or replacements. Budgets were predictable, and ROI calculations were straightforward.

Today, mobile device management comes with recurring and sometimes unpredictable costs. These operational expenses can grow as device fleets expand and data demands rise. Key cost categories include:

| Cost Category | Impact |

|---|---|

| Hardware | Initial capital required for tablets, smartphones, IoT devices; moderate impact on budget planning |

| SaaS & Cloud | Ongoing fees for MDM platforms, cloud storage, and dashboards; scales with data volume and number of devices |

| Security | Continuous monitoring, encryption, patching, and compliance management; high impact, failure can lead to data breaches and operational disruption |

| Data Usage | Variable costs for real-time telemetry, tracking, and IoT transmissions; medium to high impact, requires careful budgeting |

These costs transform IT spending from a predictable one-time capital expense into a dynamic operational expense. Calculating ROI now requires factoring in efficiency gains, improved customer satisfaction, and risk mitigation. Without careful planning, even technologies meant to drive growth can become financial burdens.

Conclusion

The logistics industry is undergoing one of its most transformative periods. While the explosion of devices, data security demands, real-time visibility needs, and shifting cost structures present real challenges, they also create opportunities for companies that embrace modern solutions.

By implementing a robust Airdroid Business, logistics teams can unify device operations, enforce security policies, monitor real-time data, and optimize costs — turning potential pitfalls into competitive advantages. Rather than juggling multiple platforms and workflows manually, companies can achieve smoother operations, improved customer trust, and measurable ROI.

If you want to explore how AirDroid Business can transform your logistics operations, try a free trial today and see the difference it makes.

AirDroid Business - Mobile Device Management Solution

AirDroid Business helps to manage and control the Android mobile workforce. This enables real-time monitoring of Android devices by tracking locations, geofencing, data processing and analysis, intelligent alerts, and remote maintenance.

It also provides a secure and centralized platform to manage all devices. All these make it an excellent choice to help enhance device management and security in an organization.

Leave a Reply.